In modern communication infrastructure, the installation of fiber optic cables is a critical stage. Cable blowing machines are designed specifically for underground duct installation, using high-pressure airflow to push cables quickly through pipelines while minimizing physical stress. They play a key role in urban network construction, long-distance backbone projects, and micro-duct deployments.

Among all blowing devices, pneumatic cable blowing machines and hydraulic cable blowing machines are the two mainstream categories. Although they have the same purpose, their structural design, power transmission methods, and performance characteristics differ significantly. Understanding these differences helps engineering teams select the most suitable equipment for each environment.

1.Differences in Working Principles

Pneumatic Cable Blowing Machines

Pneumatic systems operate based on aerodynamics. An air compressor generates high-pressure airflow, which enters the sealed blowing chamber and forms drag force along the cable surface. Typically, a mechanical feeder pushes the cable slightly into the duct first, after which the airflow takes over and propels the cable forward at high speed.

Key characteristics:

- Simple mechanical structure

- Fast startup and response

- Ideal for shorter distances and smaller-diameter cables or micro-ducts

This type of machine is widely used for lightweight deployment tasks where flexibility and quick setup are more important than extreme pushing force.

Hydraulic Cable Blowing Machines

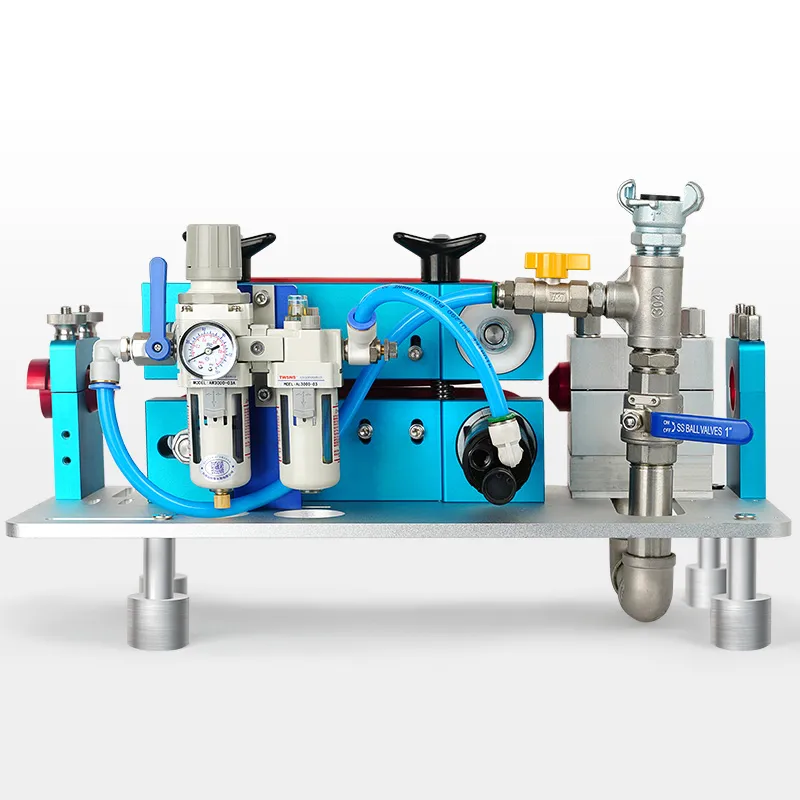

Hydraulic systems use high-pressure fluid—driven by a hydraulic pump—to transfer power to the mechanical feeder. A typical hydraulic cable blowing machine consists of the host unit, power system, and hydraulic control system.

Advantages of hydraulics include:

- Large and consistent pushing force

- High stability under load

- Excellent control accuracy

Capability to operate in harsh environments such as mountain regions or seabed cable routes

Hydraulic cable blowers are preferred for long-distance, large-diameter, or heavy cables, including armored fiber and power-supported hybrid cables.

2. Performance Differences

2.1 Thrust and Speed

Hydraulic blowing machines deliver significantly higher thrust than pneumatic systems. They maintain stable pressure output even when friction or duct resistance fluctuates, ensuring smooth forward movement of the cable.

The hydraulic is best for long runs, large ducts, heavy or armored fiber cables

The pneumatic is sufficient for light-duty, short-range, or micro-duct projects

In general, hydraulic systems also achieve higher feeding speeds, improving overall construction efficiency on large projects.

2.2 Stability and Precision

Hydraulic systems allow fine-tuned control of pushing force through hydraulic valves and feedback loops. This maintains: Smooth feeding. Stable posture of the cable. Real-time adjustment to duct conditions.

By contrast, pneumatic blowing machines offer less precise control but are fully adequate for environments where ultra-high accuracy is not required.

2.3 Maintenance and Cost

Pneumatic systems:

- Fewer components

- Easy maintenance

- Lower cost of operation

Hydraulic systems:

- More complex structure

- Require regular inspection of pumps, hoses, seals

- Higher upfront and maintenance cost

However, for long-distance or high-load installations, the efficiency gains and reduced project time justify the investment in hydraulic machines.

3.Application Scenarios

Pneumatic Cable Blowing Machines – Lightweight & Flexible

Ideal for:

- Urban streets and narrow construction spaces

- Residential complexes

- Industrial parks

- Short-distance micro-duct projects

- Emergency communication restoration after disasters

Their ease of transport and quick deployment make pneumatic units a practical choice for teams handling frequent, small-scale fiber installation work.

Hydraulic Cable Blowing Machines – Heavy-Duty & High-Precision

Suitable for:

- Highways and railways

- Long-distance backbone networks

- Large public infrastructure projects

- Submarine cable sections

- Mountainous or rugged terrain

- Heavy armored or large-OD fiber cables

The stability and high thrust of hydraulic systems ensure consistent performance even in complex or high-resistance ducts.

TFN Cable Blowing Solutions

To meet diverse deployment needs, TFN offers two high-performance models:

T700CQ – Pneumatic Cable Blowing Machine

- Suitable for duct cables up to 96 cores

- Supports 6 mm+ micro cables

- Compatible with 10 mm micro-duct air-blowing

- Lightweight, fast-deploy, perfect for urban or short-distance projects

T700CY – Hydraulic Cable Blowing Machine

- Designed for heavy armored cables and long-distance ducts

- Supports 8–12 mm micro-duct air blowing

- High thrust and precise hydraulic control

- Ideal for large-scale or complex terrain installations

TFN is also a trusted manufacturer of fiber optic fusion splicers, OTDRs, and other communication-testing instruments, enabling complete end-to-end fiber installation solutions.

Contact TFN

If you are interested in TFN cable blowing machines or need professional advice on fiber cable deployment:

Email: info@admin

WhatsApp: +86-18765219251

Facebook: https://www.facebook.com/tfnfate/